Backing Cerrion: Made for Order

Despite the trillion-dollar scale of the manufacturing industry, many of us still hold an outdated view of manufacturing as low-skill repetition. Modern factories operate under both extreme operational and cognitive load. Production lines move fast, visibility is often limited, workers are spread thin, and even the smallest deviation from plan can trigger hours of downtime, life-threatening safety risks, and tonnes of wasted materials now headed for landfill.

While production lines do still involve a degree of repetitive manual work, they also now demand a tremendous amounts of complex knowledge work. Managing Europe's largest manufacturing operations is as cerebral as anything we'd categorise as 'white collar'. The best factories conduct scientific experiments to optimise their processes, and the best factory managers are teachers and innovators as much as they are leaders of people. Modern manufacturing has evolved into it’s own discipline combining mechanical engineering, precision fabrication, and supply chain logistics - and now add AI to that list.

Cerrion's AI video agents in action

Modern production demands continuous decision-making, coordination, and process engineering, but workers lack the real-time systems required to keep up with this growing complexity. This year, unplanned downtime (when output is zero) will cost manufacturers $1.4T, and these annual losses have risen a staggering 319% since 2019, as energy costs rise and supply chains grow increasinly fragile alongside broader macro volatility. Most failures are visible only in hindsight; and by the time teams notice, the damage is already done.

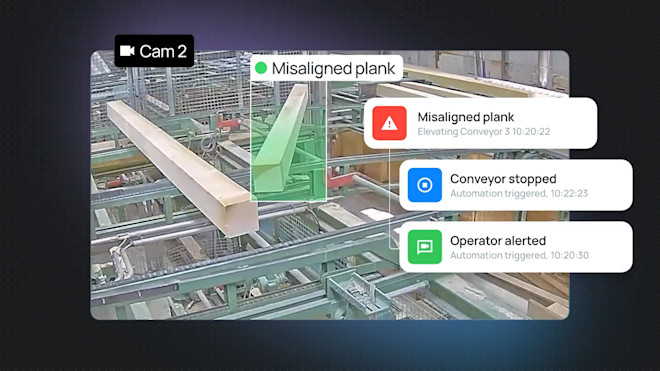

Cerrion have built an agentic AI platform that connects directly to standard factory cameras and maintains continuous oversight of critical production zones. Their agents detect process deviations, quality breakdowns, and safety hazards as they emerge, then act immediately - stopping machines, slowing conveyors, or escalating alerts. The aim is simple: remove blind spots, shorten response times, and prevent avoidable losses at the source.

Signing the TS in Zurich!

The impact is consistent: manufacturers in food, beverage, CPG, glass, wood, and building materials using Cerrion's platform now resolve issues up to 50% faster, dramatically cutting downtime and scrap, and materially strengthening their safety performance. Adoption now spans 15 countries and three continents, with many customers moving from a single pilot to multi-site rollouts once the system quickly proves itself.

At Creandum, we back the companies before it becomes obvious, and we believe firmly that manufacturing - despite its centrality to the global economy - has so far seen very little benefit from the transformative potential of AI. We believe Cerrion changes this trajectory by delivering real-time, agentic intelligence where the stakes are highest: on the factory floor. This is why we’re backing Cerrion.